BR POLYMERS

BR POLYMERS has established itself as the leading manufacturer of unsaturated polyester resin, cementing its position as a trusted and innovative player in the industry. With a strong commitment to quality and customer satisfaction, BR Polymers has consistently delivered superior products that meet the diverse needs of its clients.

As a manufacturer, BR POLYMERS operates advanced production facilities equipped with state-of-the-art technology. This allows them to produce unsaturated polyester resin of superior quality, meeting the diverse requirements of various industries. The company's manufacturing processes adhere to strict quality control measures to ensure consistent product performance and reliability.

The group started with a strong vision Mr. BABU RAM JAIN of making BR POLYMERS a renowned and trustworthy brand in Composites Industry.

What started in 1984 with a small production unit of Unsaturated Polyester Resin has now become one of the leading manufacturers in India having manufacturing unit IN KUNDLI, SONIPAT with over 10,000 MT annual capacity.

Polyester resin uses and properties

Polyester resin, also known as unsaturated polyester resin (UPR), is a versatile material that finds numerous applications across various industries. Its properties and uses include:

Composites:

Polyester resin is widely used as a matrix material in composite applications, such as fiberglass reinforced plastics (FRP). When combined with reinforcing fibers like fiberglass or carbon fiber, polyester resin forms a strong and lightweight composite structure. These composites are utilized in industries such as aerospace, automotive, marine, construction, and sports equipment manufacturing.

Gelcoats:

Polyester resin is commonly used as a gelcoat, which is a protective and decorative coating applied to the surface of composite parts. Gelcoats provide a smooth and glossy finish while also enhancing the resistance of the composite to environmental degradation, UV radiation, and corrosion.

Casting and Molding:

Polyester resin is employed for casting and molding applications, particularly in the production of various industrial and consumer goods. It can be poured into molds and allowed to cure, resulting in solid objects with desired shapes and dimensions. Polyester resin casting is utilized for creating prototypes, architectural models, decorative items, and more.

Adhesives and Sealants:

Polyester resin can be formulated as adhesives and sealants. These formulations offer good bonding strength and are used in various industries, including construction, automotive, and marine, for joining and sealing different materials.

Electrical and Electronics:

Polyester resin is utilized in electrical and electronic applications due to its excellent electrical insulation properties. It is used for encapsulating electronic components, insulation of wires and cables, and production of circuit boards.

Construction:

Polyester resin is used in construction for applications such as roofing, insulation, and decorative elements. It can be combined with fillers and additives to enhance properties such as fire resistance, UV stability, and durability.

Automotive:

Polyester resin is utilized in the automotive industry for various components such as body panels, bumpers, interior parts, and under-the-hood applications. It offers good impact resistance, surface finish, and corrosion resistance.

Properties of polyester resin include:

Good mechanical properties:

Polyester resin provides high strength and stiffness to composite structures, making them suitable for structural applications.

Chemical resistance:

Polyester resin exhibits resistance to various chemicals, including acids, alkalis, and solvents.

Excellent moldability:

Polyester resin has low viscosity and can be easily molded into complex shapes and sizes.

Fast curing:

Polyester resin cures relatively quickly when combined with a suitable catalyst, allowing for faster production cycles.

Dimensional stability:

Polyester resin maintains its shape and size over time and displays minimal shrinkage during curing.

Good adhesion:

Polyester resin adheres well to a wide range of substrates, including fiberglass, metals, and plastics.

Weather resistance:

Polyester resin offers good resistance to UV radiation and weathering, making it suitable for outdoor applications.

It's worth noting that specific formulations and modifications can further enhance or tailor the properties of polyester resin to suit specific application requirements.

OVERVIEW

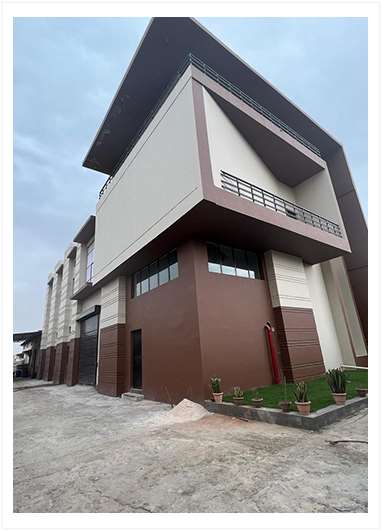

At BR POLYMERS, we have a state of the art manufacturing plant set up with a central laboratory to manufacture general and specialised resins including fire retardant resins and gelcoats and enough space for further expansions.

PLANT & MACHINERY

We have one of the latest Reactors (Plant) for manufacturing of Polyester Resins backed with excellent Testing and Research facilities to ensure quality product and batch to batch consistency.

Salient Features of the Plant

- Reactor fitted with special stirrers for fast, efficient homogenous stirring and for quick separation of By-product produced during the re-action.

- Provision for creating Inert Gas Bed during the Polymerization to avoid oxidation and hereby better colour of the finished product.

- In order to have very effective control on temperature parameter, Automatic Temperature Recorders have been fitted for both of the batch ingredients and overhead temperature which are very essential.

- We have adopted double stage plant system, which has been adopted in the International Market by the reputed manufacturers of Polyester Resins.

Production & Storage

Vision

Our Goals

- To continuously develop and improve our product line to meet the changing needs of our customers.

- To expand our reach globally and serve a wider range of industries.

- To maintain our position as a leader in the chemical manufacturing industry through constant innovation and investment in research and development.

- To reduce our environmental impact and promote sustainable practices in all areas of our business.

- To foster a culture of continuous improvement, where every employee is encouraged to contribute to the growth and success of the Company.

PLANT:

Village Pio Maniyari, District Sonipat

Haryana, Pincode-131028

HEAD OFFICE

AD - 13-A PITAMPURA, NEAR POWER HOUSE

OPP. ROHINI DIST. COURT

NEW DELHI - 110034.

CONTACT PERSON

Pranav Jain

9873445553

brpolymers8@gmail.com